Product Introduction

The rotary mixer is suitable for conventional mixing scenarios in industries such as biology, medicine, and chemical engineering. It can be put into the refrigerator or incubator.

Product Features

1. Rotary operation for gentle and thorough mixing

2. Adjustable angle range: 0-90° for single-layer adapter, 50°-90° double-layer adapter

3. Adjustable speed range: 0-80rpm

4. Accurate speed

5. Low noise

6. Multiple specifications of clips can be freely combined, suitable for 1.5mL, 2.0mL, 5mL, 10mL, 15mL, and 50mL centrifuge tubes

7. Memory function: the parameters at startup are the same as the last settings before the last shutdown

Products Parameters

|

Product Name |

Rotary Mixer |

|

Environmental temperature |

5°C~40°C |

|

Relative humidity |

≤80% |

|

Input power |

AC100V~AC240V |

|

AC power |

50 Hz/60 Hz |

|

Output power |

24 V, 1.5 A, 36 W |

|

Motor type |

Stepper motor |

|

Speed range |

10-80 rpm |

|

Time range |

1m-99h59m |

|

Angle range |

0-90° for single-layer adapter, 50°C-90° double-layer adapter |

|

Speed display |

Digital display |

|

Operating mode |

Continuous mode |

|

Voltage |

100-240 V, 50/60 Hz |

|

Input power |

36 W |

|

Dimensions |

176×260×306 mm |

|

Product weight |

2.45 Kg |

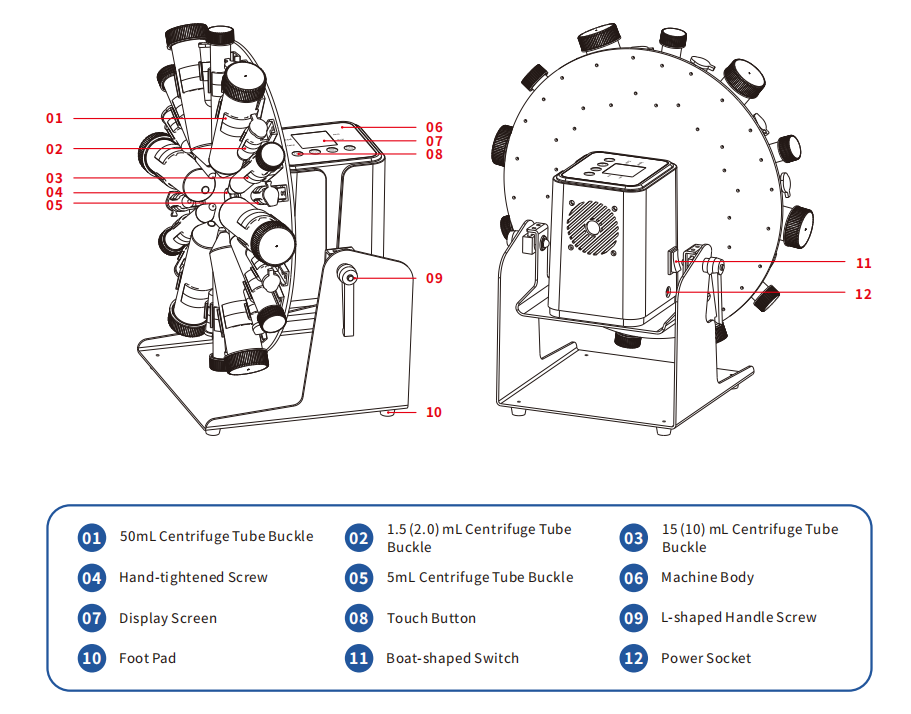

Machine Description

A. Structural Diagram

B. Optional Accessories

| Model | Description | ||

| Standard Adapter | SMV-R-A | 6×1.5(2.0)mL+6×5mL+6×15(10)mL+6×50mL | |

| Optional Adapter | SMV-R-B | 12×1.5(2.0)mL+6×15(10)mL+6×50mL | |

| SMV-R-C | 30×1.5(2.0)mL | ||

| SMV-R-D | 25×5mL | ||

| SMV-R-E | 20×15(10)mL | ||

| SMV-R-F | 10×50mL | ||

| SMV-R-G | 7×15(10)mL+7×50mL | ||

| SMV-R-H | Double-layer tray connecting rod | ||

| If you need to customize other models or modules, please get in touch with the supplier | |||

C. Installation Instructions

1. Ensure a good working environment, free from explosive and flammable materials.

2. Open the package and check whether the instrument accessories are complete, then place the instrument on a horizontal workbench.

3. If multiple instruments are used simultaneously, please maintain a distance of more than 25cm between each equipment.

4. Before connecting the instrument to the power supply, please ensure that the input voltage meets the product standard.

5. Before installing the accessories, first turn off the power, gently remove the original accessories, and then connect the replacement accessories with screws. Before each use of the instrument, please confirm that the instrument and its accessories are not damaged.

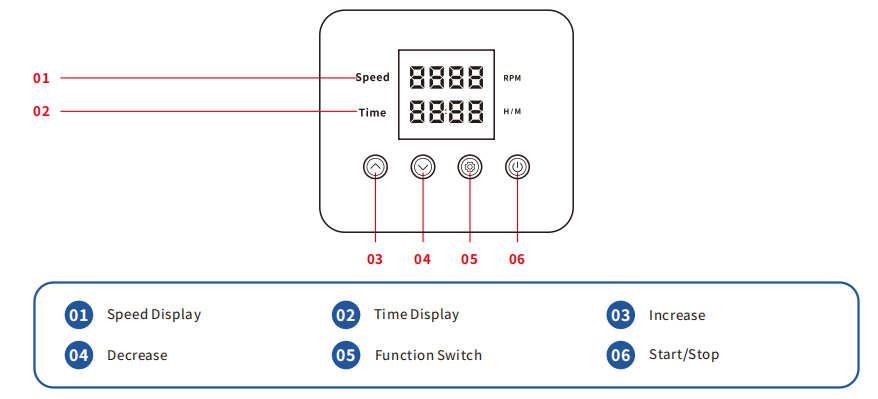

Operation Guide

I. Place the instrument on a stable, level workbench. Connect the power supply and turn on the power switch

2. Touch the "Function switch" button to select the parameter you want to set, The selected parameter will blink, Use the "increase" or

"Decrease" buttons to set it to the desired value.

3. Once the value is set, touch the"Start/Stop" button to start the instrument.

4. The instrument allows adjusting the speed during operation. If you need to adjust the time, you must pause the instrument first and

then use the function switch button to set.

5. Loosen the l-shaped handle screw to adjust the angle of the instrument. After adjusting the angle, be sure to tighten the L-shaped

handle screw to secure the angle. If you notice any angle changes during use, check if the l-shaped handle screws are tightened. it is

important to tighten both sides of the L-shaped handle screws simultaneously for better angle stability.

6. To replace the adapter, remove the hand-twist screw, align the desired adapter with the mounting hole, and then tighten the hand.

twist screw.

7. When installing the double-layer adapter, use the double-layer tray connecting rod. Press the threaded end

8. The rotator mixer has a locked rotor function. in case of a locked rotor caused by improper operation, the instrument will self-correct

and continue running. The correction process takes about 10 s.

9. If the instrument makes a "Dada Dada" noise during operation, it is determined to be caused by loose manual screw nuts. please

tighten the manual screw nuts.

Standard Adapter

(SMV-R-A 6×1.5(2.0)mL+6×5mL+6×15(10)mL+6×50mL)

(SMV-R-A 6×1.5(2.0)mL+6×5mL+6×15(10)mL+6×50mL)

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.