Product Information

|

Product Name |

Cat.No. |

Spec. |

|

Safranin O-Fast Green Staining Reagent For Bone Tissue |

G1053-100ML |

2×100 mL |

Description

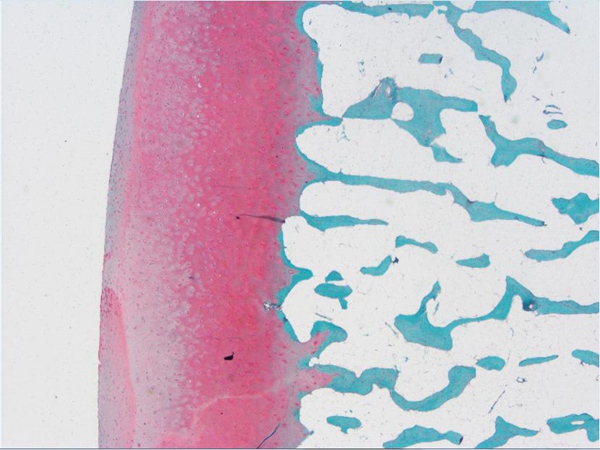

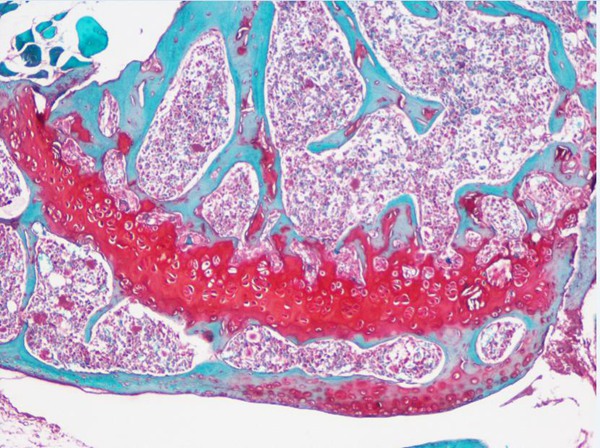

Saffranine O is a kind of cationic dye that can combine with multiple anions. It can combine with polysaccharide anion groups in cartilage tissues such as chondroitin sulfate and keratin sulfate to make it red. Moreover, the color of saffron O is approximately proportional to the concentration of anions, which can indirectly reflect the content and distribution of proteoglycans in cartilage matrix. If cartilage is damaged, glycoproteins in the cartilage are lost, showing light staining or no staining of saffron O. The acid dye fast green combines with eosinophilic components of tissues to give them a green or blue color. Cartilage and bone were distinguished by saffron - fast - green staining.

This product bone tissue saffron fast green dye solution, saffron dye solution concentration is 0.2%, the concentration of fast green dye solution is 2%. It is suitable for bone tissue staining. After staining, the cartilage is red to bright red, and the osteogenesis is green to blue-green.

Storage and Handling Conditions

Store and transport at room temperature, valid for 12 months.

Component

|

Component Number |

Component |

G1053-100ML |

|

G1053-1 |

Safranin O solution |

100 mL |

|

G1053-2 |

Fast-Green solution |

100 mL |

|

Product Manual |

||

Assay Protocol

1. Paraffin sections were dewaxed to water: sections were successively dewaxed by xylene for 10 min, followed by fresh xylene for 10 min, absolute ethanol for 5min, fresh absolute ethanol for 5min, 90% ethanol for 5min, 75% ethanol for 5min, and washed with tap water.

2. Fast green staining: The sections were stained with fast green staining solution for 1-5 min. The excess staining solution was washed with tap water until the cartilage was colorless. The sections were rapidly treated with 1% hydrochloric acid for 10-15 s, and then washed with tap water.

3. Saffron staining: Sections were stained with saffron staining solution of bone tissue for 5-10 s, and then rapidly dehydrated by four cylinders of absolute ethanol for 3-5 s each time. After the fourth dehydration, microscopic examination showed that the cartilage was red and the background was colorless.

4. Transparent sealing: Sections were transparent through xylene for 5 min, then transparent through fresh xylene for 5 min, and then sealed with neutral gum.

5. Microscopic examination, image acquisition and analysis.

Note: Prepare your own xylene, gradient ethanol, neutral gum, etc.

Note

1. The section should not be stained with saffron for too long, otherwise it is difficult to differentiate, resulting in mixed color with fast green. If you need to re-stain, you can soak in tap water to remove the fast green color, acidic differentiation solution (recommended G1039) to remove the saffrane color, and then stain again after all the colors are decolorized.

2. The excess dye can be removed by washing after fast green staining. Under the microscope, the bone formation is obviously green, and the cartilage is very light or colorless.

3. Each set of staining solution can be used for staining (dip-staining) approximately 50 sections. Replace the stain with a new one when the tissue or cell coloring is significantly lighter or abnormal.

4. Wear a lab coat and disposable gloves during operation.

For Research Use Only!

The cartilage is bright red and the osteogenesis is green.

Use collapsible tabs for more detailed information that will help customers make a purchasing decision.

Ex: Shipping and return policies, size guides, and other common questions.